History behind the Modular Lightweight Load-carrying Equipment

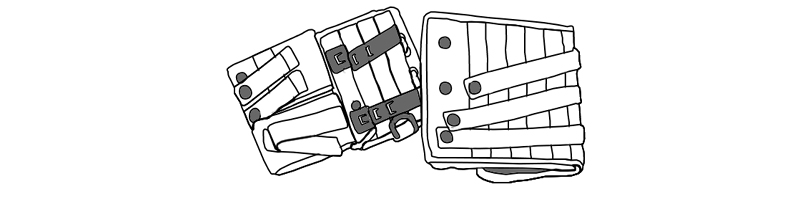

HELIUM WHISPER® has revolutionized the modular load carriage system by providing a simpler, lighter, better modular attachment system. Today’s combat load is sapped by pounds of dead nylon weight, with much of it being used in constructing the modular attachment system. Helium Whisper sets a new standard by eliminating the weight penalty of modularity.

HELIUM WHISPER® has revolutionized the modular load carriage system by providing a simpler, lighter, better modular attachment system. Today’s combat load is sapped by pounds of dead nylon weight, with much of it being used in constructing the modular attachment system. Helium Whisper sets a new standard by eliminating the weight penalty of modularity.![]()

HELIUM WHISPER® has revolutionized the modular load carriage system by providing a simpler, lighter, better modular attachment system. Today’s combat load is sapped by pounds of dead nylon weight, with much of it being used in constructing the modular attachment system. Helium Whisper sets a new standard by eliminating the weight penalty of modularity.

MILLS BELT

YEAR: 1877

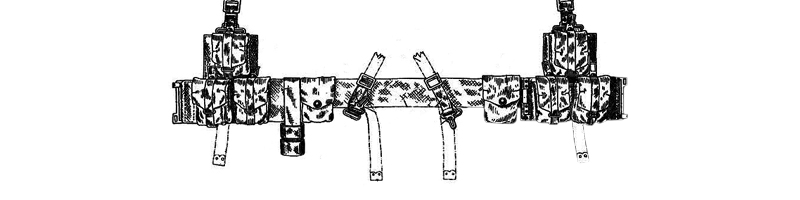

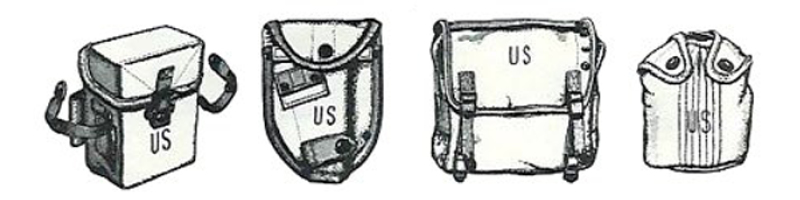

M1956LCE

YEAR: 1956

M1967 and ALICE LCE

YEAR: 1967

Similar to the M1956LCE, ALICE consisted of a modular belt with enhanced suspenders as a platform for the modular pouches. The heavy, environment-susceptible cotton duck fabric was replaced with lighter nylon fabric and webbing. Plastic and aluminum hardware also replaced with the heavy corrosion-prone brass and steel.

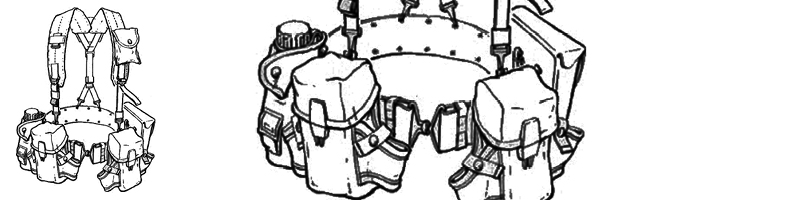

LBv88 / ILBV

YEAR: 1988

An addition to the ALICE system, the LBV88 / ILBV added a vest portion to the long-serving “pistol” belt adding both comfort and the ability to carry more equipment distributed evenly across the chest and waist employing the same heavy ALICE clips made of metal.

MOLLE

YEAR: 1997

MOLLE

YEAR: 2011

Qucik Tech Specs

LESS COMPONENTS = LESS FAILURES & LESS WEIGHT

LEGACY MOLLE

83.8 GRAMS

HELIUM WHISPER

6 PARTS

>

Load Carriage Evolution

For the next 100 years, other variations of the cartridge belt emerged using a similar cotton-canvas material. Though very durable, it was heavy and retained moisture which caused it to become even heavier in we or damp conditions.

Modularity first appeared with the adoption of the M1956 LCE. Previous versions of the modular belt system were designed for one specific ammunition type – the M1923 for the M1 Garand and the M1926 for .30 automatic rifles. The M1956 allowed for adaptable use of different pouches for different weapon systems and remained in service until the 1980s.

In 1997, MOLLE was released, ushering in the current era of load carriage. The Modular Lightweight Load-carrying Equipment featured straps on modular pouches that were woven onto Pouch Attachment Ladder System (PALS) platforms and then snapped in place. The nylon material was replaced with a heavy-duty nylon popularly known as Cordura® and the heavy ALICE clips were eliminated.

A total weight of an individual soldier’s uniform, armor and carrier, standard suit of MOLLE gear, weapon, and the soldier himself is well over the maximum doctrinal fighting weight. This doesn’t take into consideration water, mission-essential equipment, communications, first aid, or even ammunition. Pounds of dead nylon and redundant webbing are carried around, burdening every warfighter.

As the US military entered the jungles of Vietnam in the 1960s, deficiencies of the 100-year-old “duck” canvas became apparent. Mildew quickly deteriorated the canvas from the constant wetness despite attempted treatments. The M1967 was created by replacing the cotton canvas with nylon canvas and webbing and designated MLCE, Modern Load Carriage Equipment. The hardware was also replaced with lightweight, corrosion-resistant plastic and aluminum. Entering service in 1968, the MLCE never fully replaced M1956 equipment.

In 1973, the US Army adopted ALICE, All-Purpose Lightweight Individual Carrying Equipment, as a further refinement of the M1967 load carriage. Modularity was standardized with metal ALICE clips that attached to hard points on the pistol belt and later the LBV99/ILBV vest. Though lighter and more durable than the M1956 system, ALICE was still not optimal for soldiers’ needs.

Parasitic weight is the underlying concern Helium Whisper works to correct. Helium Whisper reduces excess materials, hard parts, complexity and weight while maintaining modularity and offering additional benefits over current issue equipment. The Helium Whisper™ attachment system saves 20 to 60 percent over legacy MOLLE equivalents, reducing the unbelievable weight burden of the modern warrior.

MORE EFFECTIVE GEAR MEANS A MORE EFFICIENT ENGAGEMENT